Construction Standards & Methods

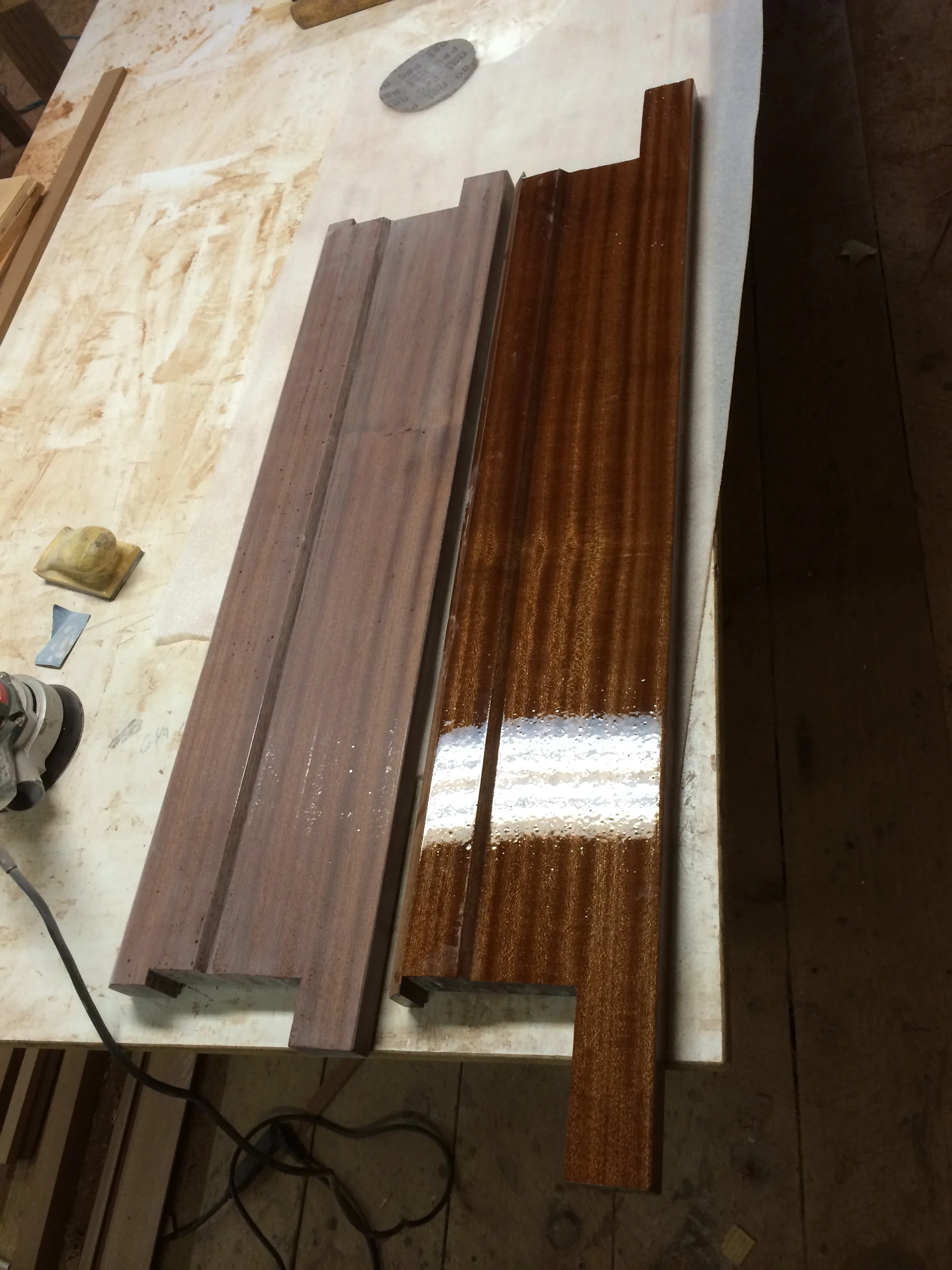

Quarter Sawn Lumber

Longevity begins with quality lumber. We use only quarter sawn lumber which is desirable for its dimensional stability. Sapele is used primarily because of its reliable stability, hardness and fair cost. Similarily as stable, Douglas fir, is slightly lighter but more costly. Both exhibit beautiful grain when clear coated.

Epoxy Coated Thresholds

Due to constant foot traffic, thresholds must be resistant to abrasive granules, therefor we epoxy coat them for added durability.

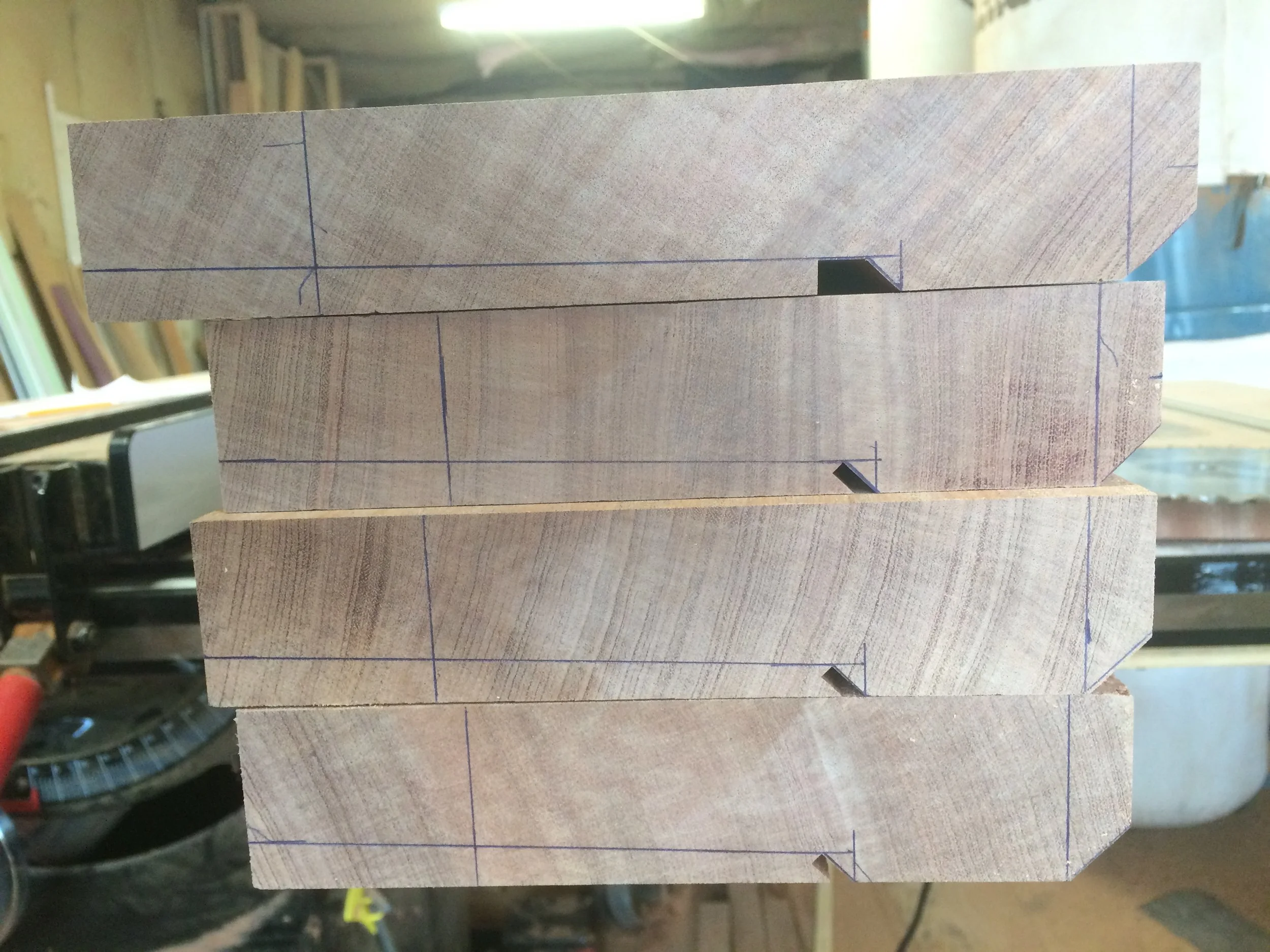

Loose Tenon Joinery with Epoxy

Also known as floating tenon joinery, describes the use of an oversized "biscuit" inserted into a mortise, on either adjoining surface. This is an economical alternative to traditional mortise and tenon, and provides the same strength, at only a fraction of the labor. This approach paired with West System epoxy, ensures extremely strong, properly bonded joints.

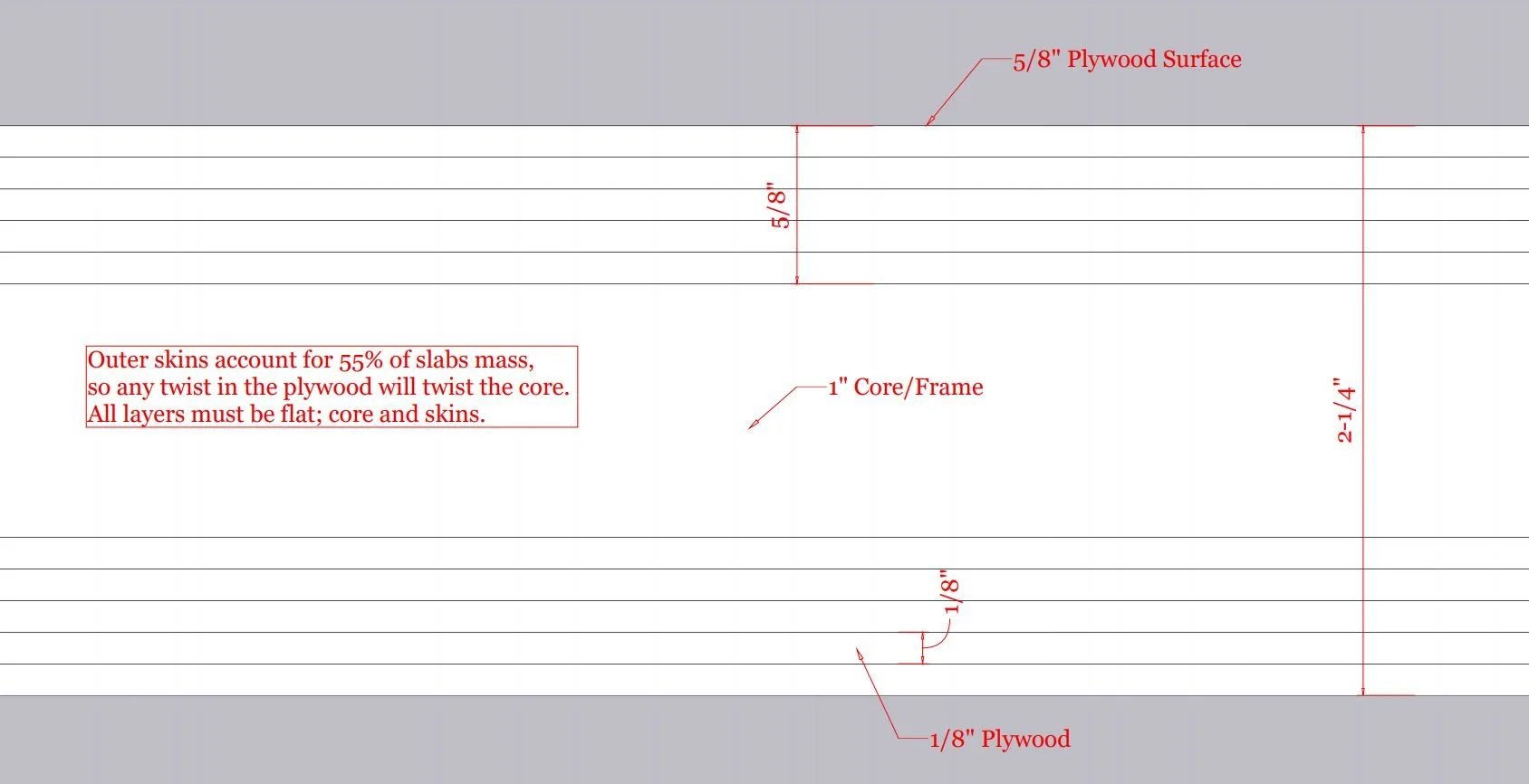

Shop Laminated Plywood

For “flush surface” doors, versus “frame and panel”, the outer surface or skins is typically Marine Grade Plywood laid over an insulated “core”. In the case of these “flush surface” doors where several layers are combined to achieve final thickness, the flatness of the outer plywood is critical in keeping the finished door assembly flat. Often, manufactured plywood is not truly flat, so we laminate our own plywood, typically from 1/8” sheets, to create 5/8” plywood, that is perfectly flat, and contains more glue lines, aiding in its rigidity.